CMC MCS 60000

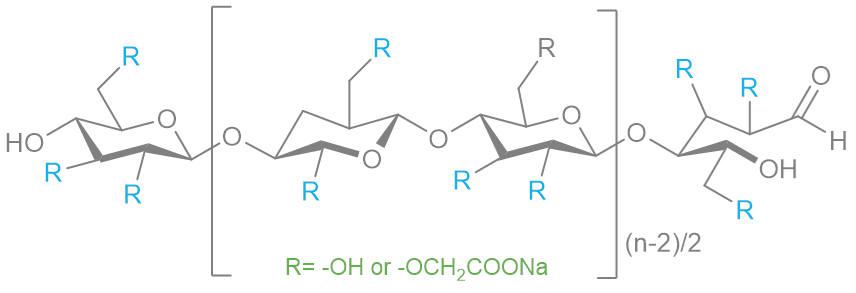

CMC MCS 60000 is a surface-treated sodium carboxymethyl cellulose specifically designed for coatings. Its specialized treatment provides delayed solubility characteristics similar to HEC, making it easier to disperse during the paint making process and effectively preventing lump formation. As an ionic cellulose ether, it offers excellent hydrophilicity and superior color development compared to non-ionic cellulose ethers, which also makes it widely applicable in textile printing and dyeing processes

CMC MCS 60000 >>>Surface-Treated CMC for Easy Dispersion and Non-Caking

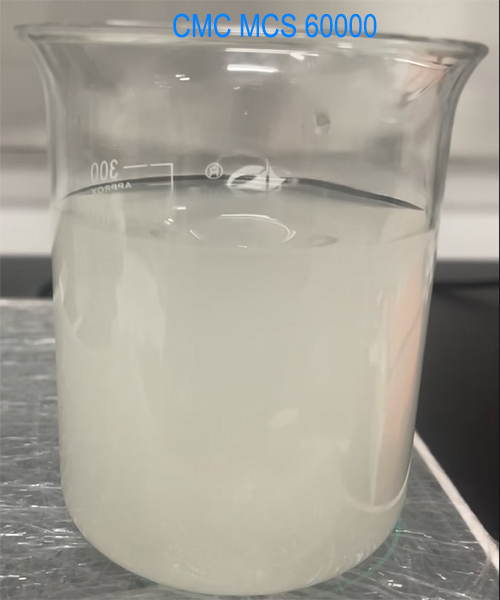

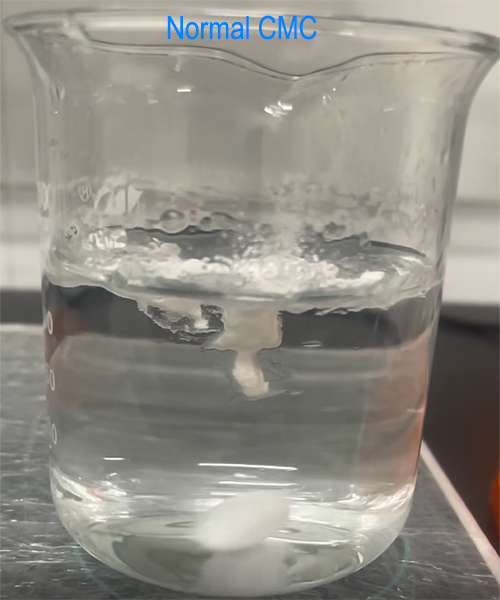

CMC MCS 60000 undergoes a special surface treatment that delays its dissolution. When added directly to cold water, it disperses rapidly without dissolving immediately—much like HEC—thereby effectively preventing the lumping issues caused by rapid swelling. Subsequently, with stirring or the addition of a small amount of pH-adjusting agent, the product hydrates quickly and reaches its maximum viscosity.

This technology not only significantly reduces dissolution time but also fundamentally avoids the “fish eyes” and gel particles commonly associated with conventional cellulose ethers. As a result, it ensures the production of coatings with a more uniform and fine texture.

As shown in the figure, MES 60000 instantly forms a homogeneous dispersion upon water addition, followed by a gradual hydration process. In contrast, conventional CMC hydrates immediately upon contact with water and tends to float on the surface.

CMC MCS 60000 >>> Excellent color development

The key advantage of CMC MCS 60000 lies in the superior hydrophilicity derived from its ionic structure. It offers perfect compatibility with water-based color pastes, ensuring brilliant color performance and making it a critical choice for high-performance multicolor coatings and textile applications.